This brief analysis summarizes the structural, construction, and environmental systems employed in the design of TKTS Booth located in Times Square, New York City, NY. The analysis will pay particular attention to the structural integrity and innovative design made possible with the latest advances in glass technology.

Project Description

Architect, site, and concept

Architect, site, and concept

Opened in 2008, the TKTs ticket booth is essentially a series of red resin steps rising from ground level atop a steel frame. The steps function to form both a roof for TKTS’s operations as well as a grandstand for people to sit within Times Square. This sophisticated glass structure was based on a competition-winning concept by the Australian architects John Choi and Tai Ropiha while the overall structure was designed by Perkins Eastman Architects. Dewhurst Macfarlane & Partners also collaborated as the structural engineers.

The original competition simply asked for a small scale structure to replace the existing 1970’s ticket booth located within the middle of Father Duffy Square on Broadway and 47th Street. Choi Ropiha went a step further in their solution and presented a scheme that acknowledged the spatial character of Times Square being one of the world’s great gathering places. Their proposal to create a grandstand was rooted in the notion of urban theater and was intended to enhance the Times Square experience by allowing visitors to stop and observe the continuous on-goings.

Structure

Glass is the primary material used in this structure while steel is a secondary material. Interestingly, all the glass components that are in this project are comparably stronger than their steel counterparts. Also, the structural loading calculations were cased on potential activities resulting in crowd behavior (sitting dancing jumping). Essentially, the structure can withstand twice its loading occupancy.

Essentially the structure is made up of three parts:

Twenty five, 30 foot long laminated glass stringer beams support red tinted glass treads between load bearing walls. The beams are made from six layers of glass; laminated in pairs, and then spliced together on staggered lengths. They are also heat-strengthened to increase strength and durability and are connected with metal bolts to the walls. These beams were held to a 2-mm tolerance over the course of the entire span.

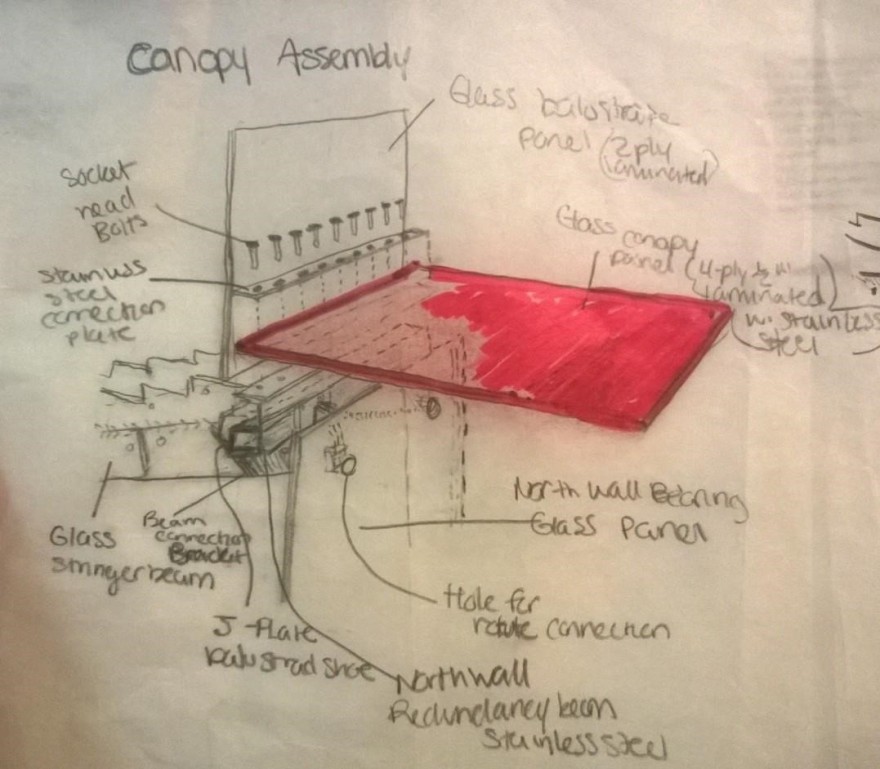

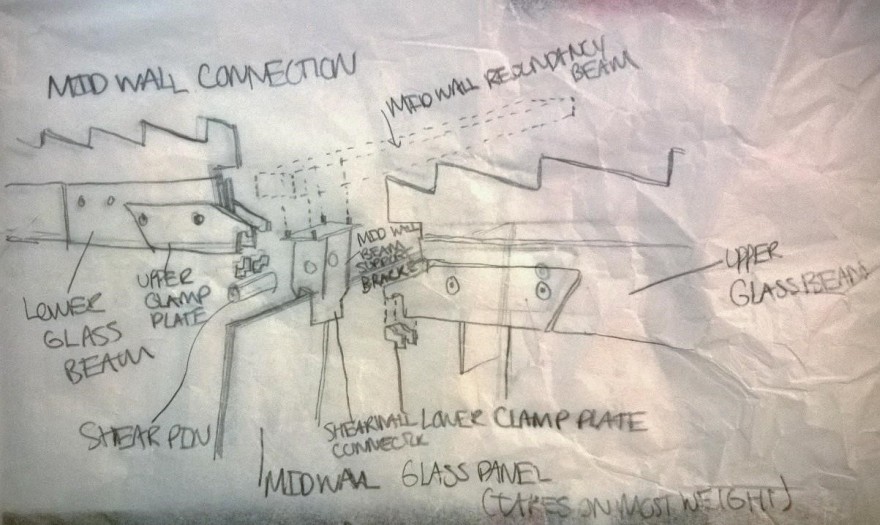

The outermost stringer beams are attached to the perimeter glass panels with pins, and the beams connect at the top of the staircase to load-bearing glass walls at the ticket window and at the midpoint with bracketed joints—the stainless steel plate and hardware of which constitute the majority of the metal in the assembly.

Treads

There are a total of 27 steps supported by a central saw-toothed section. These treads have been heat strengthened and have a non-slip surface made from ceramic frit that has been bonded by heat through a silk screen process. The steps terminate in a large cantilevered canopy that protects the ticket buyers. LED lights, housed below the treads and accessed via the risers, illuminate the structure.

Load-bearing Walls

The glass bearing are constructed of 2″ inch thick glass panels. These walls help support the weight of the treads and at maximum measure 7-feet-wide and 17-feet-tall. At the midpoint of the trusses—that weigh nearly 3,000 pounds apiece—a seven layer glass bearing wall comprised of four 1/2-inch-thick laminations of tempered low-iron glass and three layers of red PVB interlays. This wall alone carries approximately half of the structures weight.

Cantilevered Canopy

The load bearing walls also allow for a 6ft long cantilever to form a roof over the ticket booth patrons. This canopy, also glass, extends from the red glass treads.

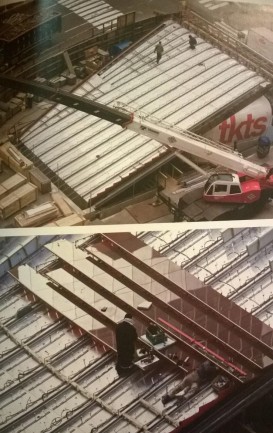

Construction

The mechanical system and the body of the structure were prefabricated. Interestingly, the designers enlisted the particular help of an America’s Cup Yacht builder constructed the fiberglass shell. The reason why the majority of the parts were prefabricated was simply because of the complications that would ensure from shutting down portions of Time Square not to mention the logistics of navigating construction amidst the congestion. Prefabrication essentially, eased and expedited construction; and with the help of just one crane the structures was skid mounted, and dropped into position in a matter of hours. While this sounds fairly simple the projects timeline was actually fairly long due to the politics of the project. Simply put funding was a major issue in this project and delayed it significantly.

Environmental systems

Due to the scale of this project the environmental systems employed were few. One defining feature is the geothermal system of five wells located 450 feet below Times Square. This system delivers a solution of water/glycol down below Broadway and back up again to heat exchangers (radiant panels) to heat and cool the space according to season. The air handling system includes high efficiency filtration to improve indoor air quality for the occupants in the ticket booth and maintain a clean interior by reducing dust accumulation on the interior surfaces.

Summary statement

The TKTS booth in New York City is a contemporary structural feat which is also aesthetically appealing. It demonstrate the capacity that structural glass has in as a building material that not only allows people to peer out to outside world from within a structure but it can also bring them to the outside world.

Resources

Killory, Christine, and René Davids. “TKTS Booth New York New York. “Details, Technology, and Form. N.p.: n.p., n.d. 152. Print.

“TKTS Booth / Perkins Eastman, Choi Ropiha.” ArchDaily. ArchDaily, 01 Dec. 2008. Web. 05 May 2015. <http://www.archdaily.com/9645/tkts-booth-perkins-eastman/>.